With a busy lifestyle, the demand for frozen food is rising every day, and when it comes to frozen french fries, they are loved by everyone in the house, from kids to older people. But have you ever thought about how these frozen fries are made?

Behind every crunchy bite of frozen french fries lies a carefully planned, technical process that turns raw potatoes into uniformly cut, partially cooked, and perfectly preserved fries. In this blog, we’ll take you deep into the production line and unveil how frozen French fries are manufactured — from farm to freezer — with an emphasis on quality, hygiene, and taste.

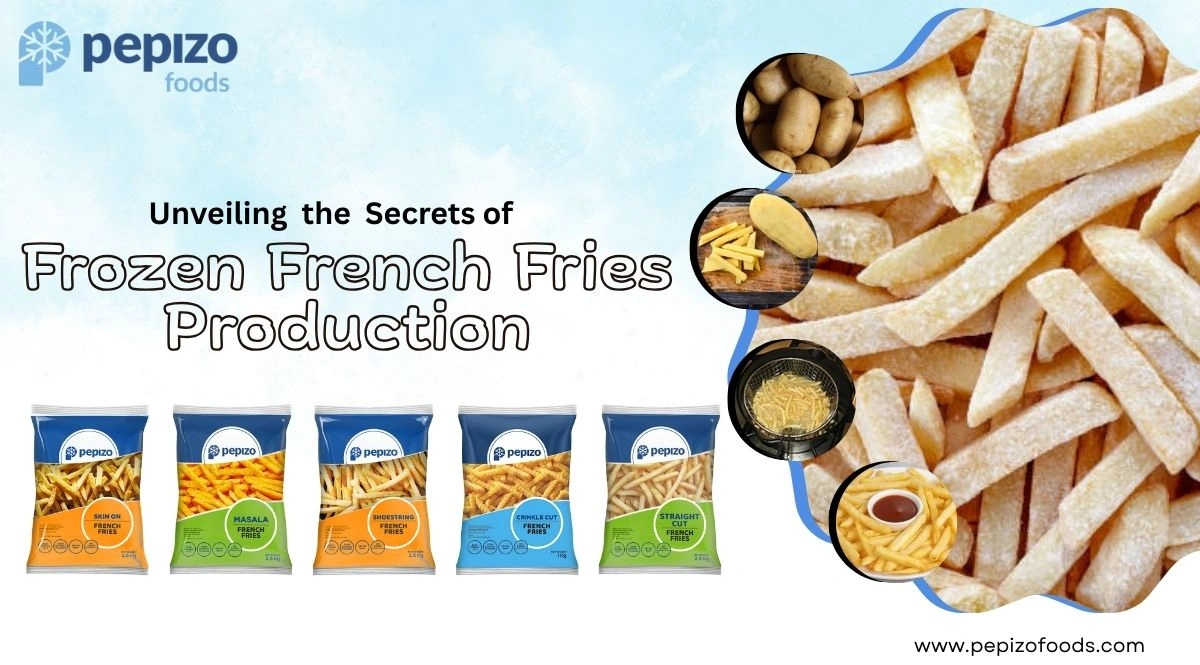

The Frozen French Fries Production Process – Step by Step

At Pepizo Foods, we follow a strict and scientific approach to produce frozen French fries that meet international quality standards. Let’s walk through the core stages that make this process truly fascinating.

1. Potato Selection – It All Starts at the Farm

At Pepizo, we don’t just make fries — we grow them. We raise our high-starch, low-moisture potatoes because not every potato is fry-worthy. Growing them ourselves means we control the quality from soil to serving. The result? Fries that are crispy on the outside, fluffy on the inside — just the way they should be.

2. Sorting and Washing – Preparing the Raw Material

Once the potatoes arrive at the facility, the first step is cleaning. They’re sorted by size and quality, then passed through automated washers that remove all dirt, stones, and impurities. High-pressure water jets and brush rollers ensure the potatoes are not only clean but also free from any soil-borne contaminants.

3. Peeling – Removing the Outer Layer

Next, there is the peeling process. Steam or abrasive rollers are used in the mechanized peeling of potatoes. This is a very quick process but gentle enough to keep nutrients from the skin intact while providing a smooth surface for cutting. Some manufacturers choose steam peeling; in this process, potatoes are subjected to high-pressure steam for a short period and then cooled down instantly, which helps in loosening the potato skin and makes it very easy to fall off.

4. Cutting – Uniform and Precise

It's now time to shape the fries into their legendary form. Potatoes are inserted into automated cutting machines where they are cut into uniform strips — usually 6mm, 9mm, or bespoke sizes as clients require. Accuracy is important here. Consistency in size ensures even cooking and uniform texture in every batch.

5. Rinsing – Removing Surface Starch

After cutting, the fries go through a cold water rinse to remove surface starch. This step prevents the fries from clumping together and helps maintain their light color. At Pepizo, we use multiple rinse cycles to ensure maximum clarity and cleanliness of the product before the next stage.

6. Blanching – Pre-Cooking for Better Texture

Blanching is a brief heating process where the fries are dipped in hot water or steam for a few minutes. This helps:

- Inactivate enzymes that could cause discoloration

- Maintain color and texture

- Partially cook the fries

- Reduce microbial load

7. Drying – Removing Moisture

Before pre-frying, the fries are passed through air dryers or vibratory dryers. This removes excess surface moisture, which is essential for:

- Preventing oil splatter during frying

- Ensuring better oil absorption control

- Achieving uniform crispiness

8. Pre-Frying – Locking in the Crunch

For pre-frying, fries are partially fried in vegetable oil for a very short time, like barely a minute or more. It creates a kinda protective crust on the outside while keeping the inside soft. It’s not deep-frying — just enough to create that crispy outer layer once the fries are reheated later by the end user.

9. Flash Freezing – Preserving Freshness

Immediately after pre-frying, the fries are cooled and then blast-frozen at -18°C. This rapid freezing locks in taste, texture, and nutritional value without forming large ice crystals. Quick freezing also ensures that the fries don’t stick together in the final packaging.

10. Packing – Sealed and Safe

The frozen fries are now packed using automated, hygienic systems. At Pepizo, we use vacuum-sealed or nitrogen-flushed bags to increase shelf life and avoid oxidation. Each pack is weighed, sealed, and labeled with batch info, storage instructions, and expiry dates. Our quality control team inspects each lot to ensure international food safety standards are met.

India’s Frozen French Fries Industry: A Rising Star

India is becoming a hub for the manufacturing of frozen French fries, both domestically and worldwide, due to growing demand. With widespread agricultural resources, trained human resources, and better cold chain facilities, French fries from India are blooming.

Why Choose Frozen French Fries from India?

- Competitive pricing

- High quality and food safety standards

- Diverse product options and cuts

- Reliable export networks

At Pepizo Foods, we’re proud to contribute to this growth by producing export-grade frozen fries for both domestic and global clients.

Why Choose Pepizo Foods?

We're not some regular frozen French fries manufacturer in India, We're here to stand for quality along with taste. We've discovered and applied safe, hygienic, and consistent processes to make our products stand apart from the others.

✔️Grown our premium Indian potatoes

✔️ No preservatives or artificial additives

✔️ Hygienic, automated production

✔️ Stringent quality control

✔️ Customizable cut sizes and private labeling options

Whether you're a food distributor, retailer, restaurant, or international buyer — we offer solutions tailored to your needs.

Conclusion

The journey of frozen French fries — from the potato in the soil to the delicious treat on your plate — is a blend of science, precision, and passion. At Pepizo Foods, we craft every step of the process carefully so that we can provide fries not only as a tasty treat but also as a safe, convenient, and dependable one.

Let’s Fry Up Some Business!

Are you looking for a trusted frozen french fries manufacturer in India?

👉Explore our range here…

👉 Contact us for inquiries, bulk orders, or private labeling.